JE Pistons Official UK Distributor

JE Pistons Advantage

JE Pistons is a well-known manufacturer of high-performance pistons primarily used in racing and high-performance applications for automobiles, motorcycles, boats, and other vehicles. The company was founded in 1947 and is based in Huntington Beach, California, USA.

JE Pistons specialises in designing and manufacturing pistons that are used in engines with demanding performance requirements, such as those in racing cars, high-performance street vehicles, off-road vehicles, and more. Their pistons are made from high-quality materials and undergo precise engineering to meet specific performance goals, including increased horsepower, improved durability, and enhanced efficiency.

JE products are used by professional racing teams, engine builders, and enthusiasts seeking top-notch performance and reliability for their engines. JE Pistons is recognised for their expertise in piston technology and their commitment to providing high-quality, reliable solutions for the performance automotive industry.

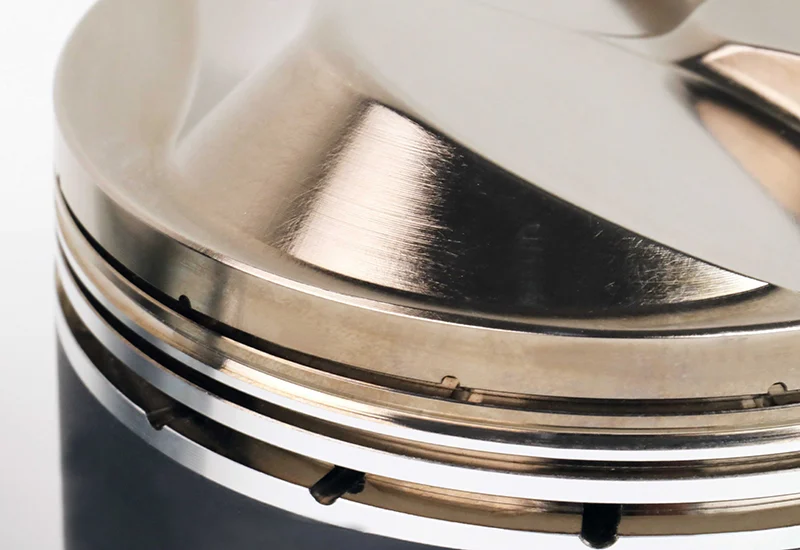

Introducing JE’s Feature-Rich, Big-Power-Ready Ultra Series Pistons

Ultra Series pistons combine JE’s premium features and all-new, industry-first technology into an off the shelf piston kit! This includes aligned grain flow technology, a proprietary JE technology that aligns the grain flow in critical areas of the piston to improve strength, and many other high-end features.

Perfect Skirt coating

is one of the many technologically advanced aspects of the Ultra Series. It protects the piston skirts, reduces friction, while eliminating cold-start piston slap and false knock on computer-controlled engines.

Ceramic crown treatment

A spray-on coating that’s baked on to the piston. This coating reflects the heat of the combustion away from the piston, and that enables you to run at high heat levels without the piston pulling in all the heat and softening.

Lateral gas ports

Helps to achieve the best ring seal possible. Vertical gas ports have a tendency to get clogged and cause premature ring failure. A lateral gas port doesn’t apply the same amount of pressure but it’s a lot more pressure than you’d have without them, and your rings won’t wear out as quickly.

Thicker, premium-material wrist pins

another strength-boosting feature of the Ultra Series line. Combined with unique Grain Flow Optimized forging technology, the Ultra Series is ready for huge power.

Accumulator grooves

Essentially notches in the material between the top and second ring to reduce pressure build up. Because of the added volume, the pressure caused by any gases that pass by the top ring are reduced, and that prevents the top ring from being unseated

Aligned Grain Flow Technology

Like wood, metal has a grain to it, and you want the forces applied to that material to be aligned with the grain rather than against it. Using a proprietary forging process called Aligned Grain Flow Technology, JE engineers are now able to precisely control metal grain direction around key structural elements of the piston. This process yields significant strength improvements, and an exceptionally robust part overall.

Premium carbon steel piston rings

help Ultra Series pistons seal big boost for maximum power output.

Custom Automotive Pistons

JE Pistons offers custom piston manufacturing services, allowing customers to create pistons tailored to their specific needs and requirements. Custom pistons are designed to meet unique specifications, including bore size, compression ratio, material selection, piston shape, and other factors crucial for optimizing engine performance.

We can work closely with JE Pistons’ engineering team to design pistons that align with your goals, whether it’s enhancing horsepower, improving efficiency, or accommodating specific engine configurations. The process typically involves providing detailed information about the engine, desired performance goals, and any specific constraints or preferences.

JE Pistons’ expertise in custom piston manufacturing ensures that the final product meets the necessary performance criteria and fits seamlessly into your engine..

Custom Piston Options

Thermal Barrier Crown Coating

Applied to the top of the piston and is designed to reflect heat into the combustion chamber, thereby increasing exhaust gas velocity and greatly improving scavenging potential. The .0015” thick coating can also assist in extending piston life by decreasing the rate of thermal transfer.

TUFF SKIRT ® Coating

JE Pistons’ trademark coating that is a lubricating, anti-friction/anti-wear coating applied to the piston skirt only. Unlike our standard Skirt Coating, Tuff Skirt will not wear and is designed to withstand many different types of endurance applications, similar to those commonly found in NASCAR. Buildup is .0005” per surface and finished diameter of skirt should include the coating buildup.

Anodized Ring Groove Coating

Reduces wear and material transfer between the ring and groove. Shown to be very durable in maximum effort, high endurance applications. Appropriate manufacturing allowances apply.

KoolKote

Is an aerospace quality hard anodize applied to all surfaces of the piston with a buildup of .001. This coating is designed for use in nitro-methane engines such as Top Fuel Drag Racing to endure the corrosive effects of this type of fuel. It will withstand greater temperatures and will not flake, chip or peel. This coating does alter the heat transfer and expansion characteristics of the piston. Consult the JE Pistons technical department for specific applications. Manufacturing allowances are required on all surfaces.

Perfect Skirt™

Perfect Skirt is a proprietary and patented skirt coating only offered by JE Pistons. Perfect Skirt is three-times thicker than traditional skirt coatings to allow racing pistons to have tighter piston-to-wall clearances similar to OEM applications. This decreases piston noise on startup and reduces cylinder bore wear. Additionally, this is beneficial for late-model engines, reducing the possibility of false knock sensor readings. Perfect Skirt will continuously conform to the shape of your cylinder’s bore.

EN Plating

Help reduce pitting and piston ring micro welding caused by detonation with JE’s Electroless Nickel plating. Unlike other metal plating that loses hardness and softens when exposed to heat, Electroless Nickel gets harder as it runs. The plating is applied to the piston domes, ring grooves, and wrist pin bore to provide a lower coefficient of friction, reduce ring blow-by, and increase detonation protection. In addition, Electroless Nickel reflects heat and allows domes to run up to 68 degrees cooler.

DEDICATED FORGINGS

JE pistons are produced from in house manufactured dedicated forgings.

SKIRT COATINGS

anti-friction skirt coating reduces the harsh contact between the piston skirt and cylinder bore.

STEEL NITRIDED RINGS

Supplied with Steel nitrided performace ring packs

OPTIONAL PIN UPGRADES

Tool steel pin upgrades available for extreme power engines

BMW

BMW Ford

Ford MINI

MINI Porsche

Porsche Vauxhall

Vauxhall VW / Audi

VW / Audi E46 M3

E46 M3 E90 / E92 M3

E90 / E92 M3 F82 M4

F82 M4 F22 M240i

F22 M240i Focus RS MK 1

Focus RS MK 1 Focus RS Mk 2

Focus RS Mk 2 Focus RS MK 3

Focus RS MK 3 Focus ST MK 3

Focus ST MK 3 Fiesta ST150

Fiesta ST150 Fiesta ST180

Fiesta ST180 Sierra Cosworth

Sierra Cosworth Escort RS2000

Escort RS2000 MINI Cooper S R53

MINI Cooper S R53 MINI Cooper S R56

MINI Cooper S R56 MINI Cooper S F56

MINI Cooper S F56 MINI Cooper F56

MINI Cooper F56 Astra H VXR

Astra H VXR Astra J VXR

Astra J VXR Corsa D VXR

Corsa D VXR Corsa E VXR

Corsa E VXR Audi TTRS

Audi TTRS Audi RS 3

Audi RS 3 Golf 6 GTi

Golf 6 GTi Golf 7 GTi

Golf 7 GTi